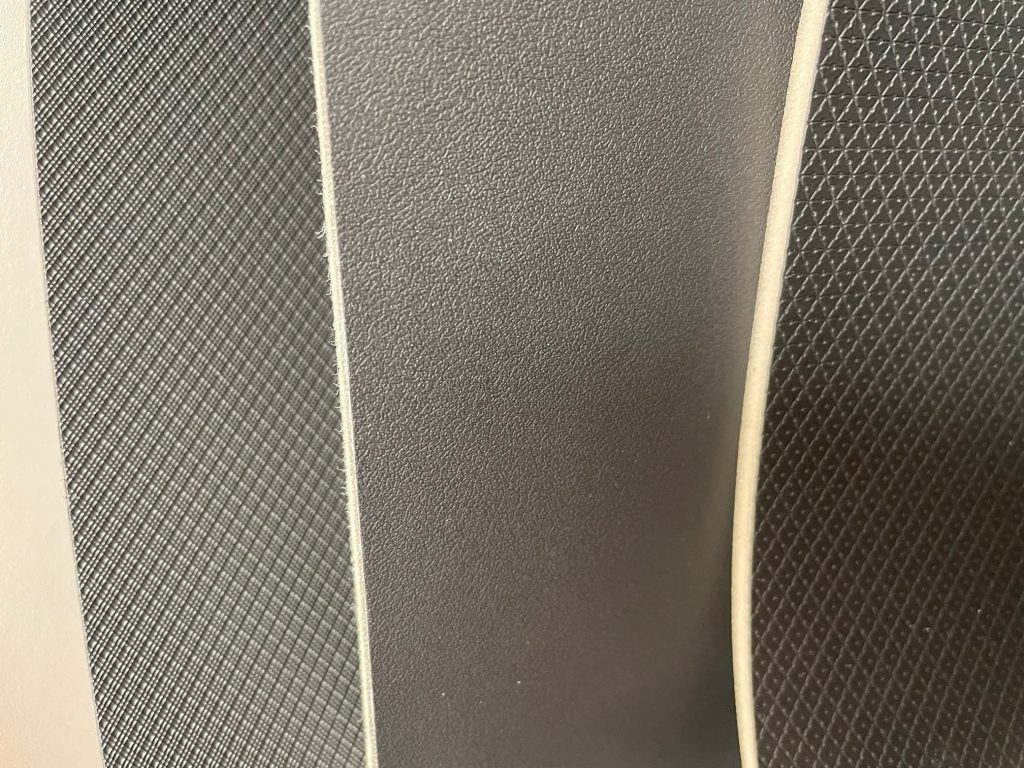

A recycled TPO solution engineered for thermo-covering door panels – combining recyclability, surface aesthetics and processability.

Recyclable, mono-material, and process-ready — our TPO range is designed to meet the industry’s toughest surface specs while simplifying complexity.

Up to 28% recycled Polyolefin content

Fully recyclable mono-material structure

Compatible with standard thermo-covering processes (IMG & PVF)

Meets high automotive standards for visible interiors

Weight saving, lighter than PVC

A recycled TPO solution engineered for thermo-covering door panels – combining recyclability, surface aesthetics and processability.

A TPO grade developed for vacuum-formed surfaces with deep geometries – for durable aesthetics and a step closer to circular design.

Let’s face it: surface materials are complex. Especially in automotive interiors, where multiple layers — lacquer, foam, adhesives — come together in tight tolerances. But if we want circularity to scale, we have to simplify. That’s exactly what our TPO range is designed to do.

By developing recyclable, Polyolefin-based solutions for the core layer — the compact layer — we enable OEMs to move toward fully mono-material skin structures. The result? Better recyclability, fewer material incompatibilities, and a more sustainable path forward for surfaces.

A typical TPO skin includes multiple layers:

A lacquer (top aesthetic finish)

A compact layer (structural support)

A foam layer (for softness and acoustics)

A primer or glue layer (to bond everything together)

At MATERI’ACT, we focus on the compact layer — the technical core that delivers structure, resistance, and compatibility with industrial processing. Our solution: Polyolefin base TPO + PP base foam + PP base glue. This combination enables a true mono-material, fully recyclable construction — no compromises.

Our TPO range currently includes two distinct technologies, each suited to a specific thermoforming process and design intent:

TPO – Thermoplastic Polyolefin: A soft-touch plastic blend, often used for dashboard skins and door panels.

IMG – In-Mold Graining: A forming process where texture is applied directly in the mold — great for high-end finishes

PVF – Positive Vacuum Forming: Uses vacuum to shape skins over foam, especially for parts with deep geometries.

Still sound niche? Don’t worry — the result is simple: beautiful, durable, recyclable surfaces.